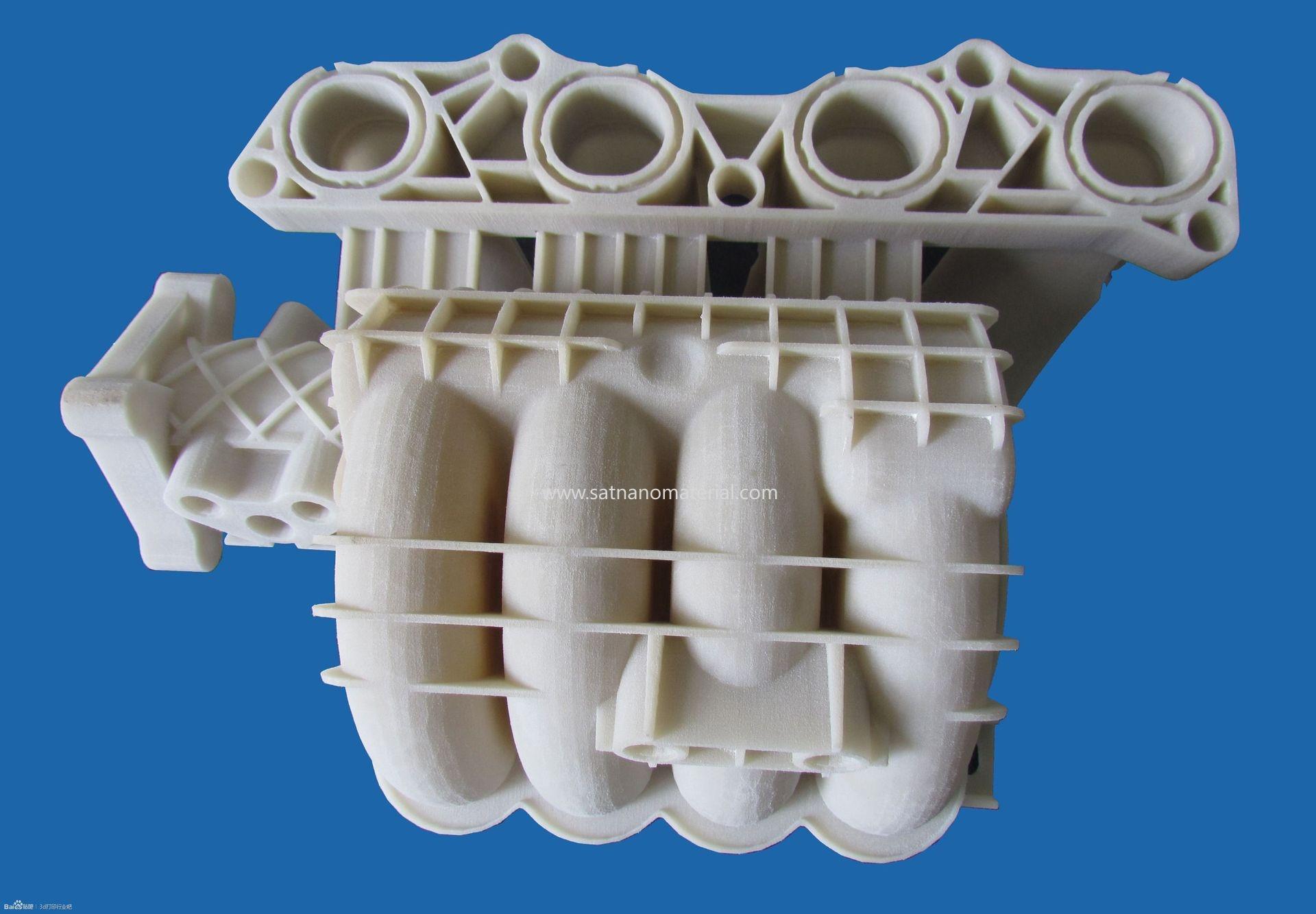

Car intake manifold

solution

1. The accuracy is +/-0.1mm, and the layer thickness of 0.02 fully meets the requirements of dimensional design verification

2. Using PA3200 nylon mixed glass fiber material, it has high strength, high toughness, and high temperature resistance, which fully meets the requirements of functional design verification

3. All parts are produced and printed at one time, no splicing, and at the same time the strength of the parts is guaranteed, completely surpassing the traditional process methods

Automobile cavity mould

solution

1. The conformal water circuit design that fits the gate wall surface provides excellent cooling speed for the gate position. The cooling time is reduced from 24 seconds to 7.5 seconds, the cooling time is reduced by 68%, and the production efficiency is improved.

2. A small amount of machining allowance reduces material consumption and processing time

3. The average injection temperature dropped from 95 degrees to 68 degrees

4. The temperature gradient drops from 12 degrees to 4 degrees

5. Mold dragging rate decreased from 60% to 0

6. Productivity increased to 3 per minute

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449