The ideal characteristics of silver coated copper powder largely depend on the perfection and consistency of the silver coating at the microscopic level. High quality silver coated copper powder is a prerequisite for realizing its application value. The core goal and difficulty of the preparation process is to achieve uniform, dense, continuous, and thickness controllable silver layer coverage on the surface of copper powder particles. At present, the preparation methods of silver coated copper powder mainly include mechanical ball milling, melting spray, chemical plating, etc

The mechanical ball milling method is to mix copper powder and silver powder in proportion and place them in a ball mill. By relying on the intense impact, friction, and cold welding effects generated by the high-speed rotating grinding ball, silver is forcibly squeezed, adhered, and cold welded to the surface of copper particles. The advantage of this method lies in its relatively simple equipment, concise process, high theoretical yield, and low cost, without involving complex chemical reactions or waste liquid treatment issues. However, the "silver layer" formed is essentially silver fragments or clumps mechanically attached and cold welded, making it difficult to achieve a uniform, continuous, pore free, and dense complete coating layer. There are problems with incomplete coverage, weak bonding force, and weak control over the coating morphology. To improve the coating effect of traditional ball milling methods, copper powder is generally shaped into flakes during the ball milling process, significantly increasing the contact area between copper powder and silver particles while shortening the diffusion path of silver atoms. This is conducive to the more effective diffusion of silver substances on the surface of copper sheets, ultimately forming silver coated copper sheets with stronger bonding force, relatively denser and more uniform coating. However, the mechanical ball milling method is prone to introducing wear impurities from the grinding balls and the tank body, posing potential challenges to the stability and long-term reliability of product performance.

02 Melting spray method

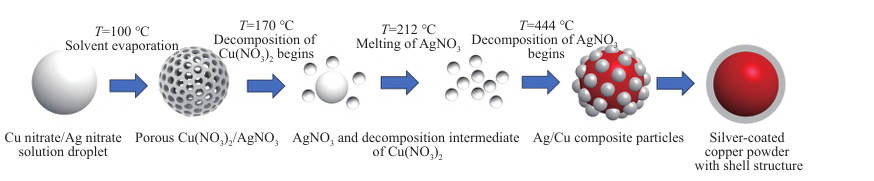

The melt atomization method is to atomize molten droplets containing copper and silver and solidify them under rapid cooling conditions. Due to the higher fluidity of silver compared to copper at higher temperatures (>900 ℃), it can migrate to the surface of copper particles and achieve coating of copper particles. Using this technology to prepare silver coated copper powder, its silver content is extremely low, but the surface silver content is very high, and the silver content gradually decreases from the surface to the interior, showing a ladder like distribution. However, the preparation process is relatively complex, the production cost is high, and it is not suitable for large-scale production.

03 Chemical plating method

Chemical silver plating is the process of reducing silver ions in a solution to elemental silver through an oxidation-reduction reaction, and depositing and coating it on the surface of a copper substrate. The advantages of chemical plating method are good uniform plating and deep plating ability, which can be applied to non-metallic and semiconductor materials. The equipment is simple and the operation is easy. It is currently the most widely used method for preparing silver coated copper powder. According to the sedimentation mechanism, chemical plating can be divided into two types: displacement method and reduction method:

① Substitution method

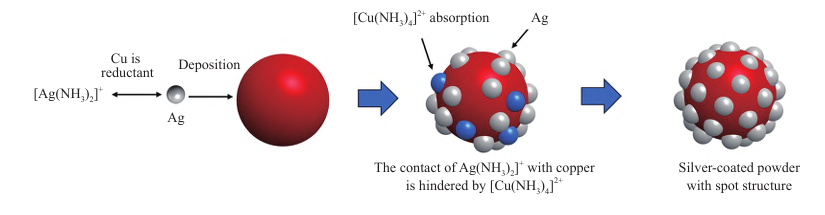

The displacement method utilizes the characteristic that the reduction potential of copper is lower than that of silver. When copper powder is immersed in a solution containing silver ions (Ag ⁺), an electrochemical displacement reaction occurs: 2Ag ⁺+Cu ->2Ag+Cu ² ⁺. Silver ions are reduced and deposited on the surface of copper powder, while copper atoms are oxidized into copper ions and enter the solution. However, due to the displacement reaction between copper powder and silver source, the copper powder is enveloped by silver coating, which hinders the progress of the displacement reaction. At the same time, the reaction rate between copper powder and silver source solution is fast, and the silver coating quickly deposits on the surface of the copper powder. Therefore, silver coated copper powder prepared by displacement method often has the problem of thin and loose coating, which affects its performance. Generally, chelating agents (such as ammonia water) can be added during the preparation process to reduce the reaction rate, allowing silver metal to slowly deposit on the surface of copper powder, or multiple silver plating can be used to improve the morphology and coating rate of silver coated copper powder.

② Restoration method

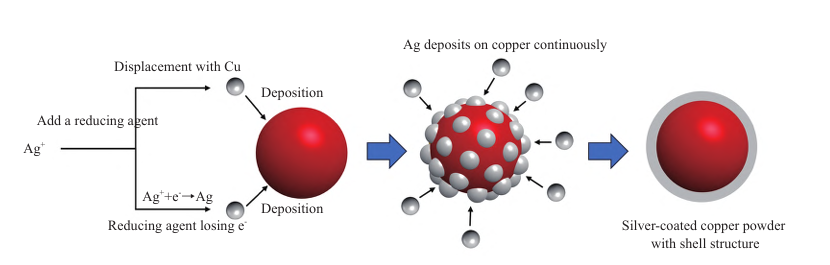

The reduction method uses reducing agents (such as formaldehyde, glucose, hydrazine hydrate, ascorbic acid) to reduce silver ions (Ag ⁺) in the solution to elemental silver and deposit it on the surface of copper powder. The reaction mechanism consists of two stages: firstly, due to the higher activity of copper (Cu) than silver (Ag), copper powder first undergoes a displacement reaction with Ag ⁺: 2Ag ⁺+Cu → 2Ag+Cu ² ⁺, forming a thin layer of silver on the copper surface. As the replacement silver layer covers the copper surface, it hinders direct contact between copper and Ag ⁺, and the replacement reaction stops. At this point, the Ag ⁺ in the solution mainly relies on the reducing agent to undergo a reaction (such as 2Ag ⁺+reducing agent → 2Ag+oxidation product), and silver continuously and uniformly deposits and thickens on the initial displacement layer, forming a denser silver coating layer.

SAT NANO is a best supplier of silver coated copper powder in China, we can supply nano particle size and micro particle size, if you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449