Firstly, we must emphasize that XRD analysis of elemental content is very inaccurate. If we have to say what the detection limit is mainly determined by, it is determined by the power and tube current of the instrument. If we want to characterize the elemental content, it is best to use chemical methods or atomic absorption spectroscopy.

In addition, the detection limit of XRD cannot be simply expressed in%, which is closely related to the dispersion of the detected substance, that is, the crystallinity, and the type of substance. The mass absorption coefficient of the sample is large, and the detection limit will be much higher.

If a detection limit must be determined, it is generally around 5%. However, different phases have varying absorption of X-rays, resulting in significant differences in detection limits. Like elemental silicon, it can generally be detected at around 1%, while other phases, up to 10%, may be difficult to detect. Of course. Under the same sample conditions, using higher diffraction power and longer scanning time will yield better results. However, if you want to extend the scanning time, extending it by one or two times will not yield any results.

Experience has shown that if a conventional scanning speed can detect any signs of existence, then scan at a speed of 1 degree/min or slower. If you can't see any traces at regular scanning speeds, there's no need to put in any more effort. Conducting semi quantitative analysis is indeed very inaccurate, and the results are indeed related to grain size. The precipitation phase with small grain size is difficult to detect, let alone perform quantitative analysis. The phase with small grain size will increase its RIR value. The RIR value of CeO2 has been studied, and the RIR values of the products at different temperatures differ by 10 times.

SAT NANO provides two examples to illustrate:

Example 1: A diamond sample was contaminated with silver, and a silver peak appeared in the XRD spectrum, which was very obvious. Through quantitative calculation, it was found that 0.04% wt of silver was present in the sample. To further confirm, spectral analysis revealed the presence of 0.038% wt silver.

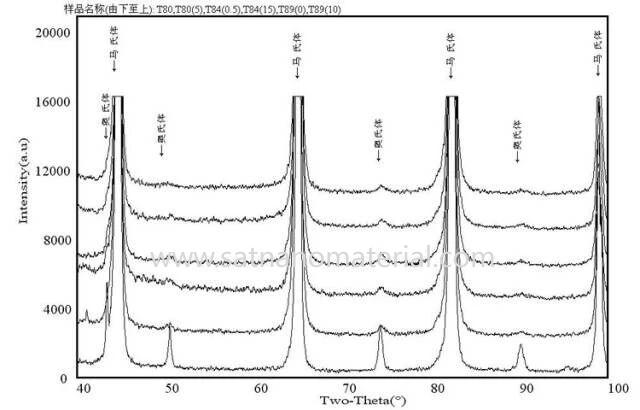

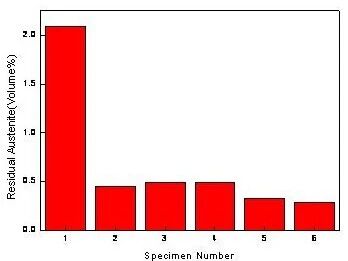

Example 2: The steel sample contains a small amount of residual austenite, and the transformation from austenite to martensite is measured after tensile fracture. The sample contains both austenite and martensite phases. The residual austenite in the sample before stretching is about 2% (V), and after the tensile test, only 0.2% to 0.5% austenite remains in the sample. According to the conventional scanning speed (8 °/min), no austenite peak can be found in the scanned spectrum. Later switched to step scanning: with a step size of 0.02 ° and a counting time of 1.5 seconds. The results were quite good.

Calculation results of residual austenite:

It is possible to measure phases with a content of less than 1% using the D/max 2500 diffractometer in physics. However, the scanning time should be appropriately extended, that is, a lower scanning speed should be used. Step scanning can obtain ideal results.

How to use XRD to detect substances with low content?

First, scan at a faster speed. When there are some seemingly ambiguous trace peaks in the spectrum, switch to scanning at a slower speed. According to experience, if you can see the "shadow" of a certain phase at 8 degrees per minute, there is not much improvement at a speed of 4 degrees per minute. It is necessary to switch to a speed of 1 degree/min or slower in order to have an effect. Another frequently overlooked factor is the size of the sample. Especially for bulk samples, the sample frame should be filled as much as possible to increase the irradiation volume, which is equivalent to prolonging the scanning time. Samples that can be made into powder should be made into powder as much as possible and compacted as much as possible.

SAT NANO is a best supplier of nano powder and micro powder in China, we can offer metal powder, alloy powder, oxide powder and carbide powder. We also can supply the XRD, SEM, MSDS of product that your enquiried. If you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449