With the increasing demand for high thermal conductivity materials, filled thermal conductive polymer composites have good application prospects. The performance of thermal conductive composite materials largely depends on the selection of thermal conductive fillers. Aluminum oxide (Al2O3)is a common ceramic filler with high hardness and good thermal conductivity, and is a commonly used choice to improve the thermal conductivity of materials.

1.Unique Advantage: The spherical structure endows a unique advantage

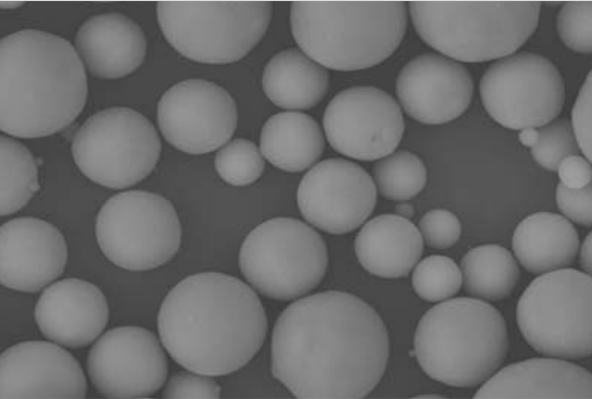

Excellent thermal conductivity. Aluminum oxide is an inorganic non-metallic material with excellent thermal conductivity, and its spherical structure further optimizes its thermal conductivity path. In composite materials, spherical particles can form a more continuous and smooth thermal conductivity network, thereby reducing thermal resistance. When heat is transferred inside the material, the contact area between spherical particles is relatively large and distributed more evenly, avoiding heat transfer interruptions caused by irregular shapes, large edges, or stacking gaps, thereby significantly improving the overall thermal conductivity of the composite material.

Excellent dispersibility. The spherical structure endows alumina powder with good fluidity and dispersibility. Compared with irregularly shaped alumina powders such as flake, needle, and block powders, spherical particles have less friction between each other and are more easily evenly distributed in the matrix material, thereby reducing the occurrence of aggregation. This uniform distribution ensures the continuity and consistency of the thermal conductivity network in composite materials, avoiding thermal conductivity fluctuations caused by local particle aggregation.

Good chemical stability and high temperature tolerance. Spherical alumina fillers have strong chemical stability and are not prone to chemical reactions with surrounding media. In acidic and alkaline environments, humid environments, or long-term use, its physical and chemical properties remain stable and will not degrade due to corrosion, oxidation, or other factors, ensuring the long-term reliability of thermal conductive materials. At the same time, it has excellent high-temperature resistance and can maintain structural integrity and thermal conductivity in high-temperature environments.

2. Preparation process: precise shaping from "powder" to "sphere"

The excellent performance of spherical alumina lies in its precise spherical structure and controllable particle size distribution, which cannot be separated from mature preparation processes. At present, the preparation methods of spherical alumina powder mainly include: flame melting method, jet method, template method, aerosol decomposition method, sol gel method, hydrothermal method, dropping ball method and ball milling method.

(1) Spray method

The preparation of spherical alumina by spray method uses a high-temperature heat source to heat treat the precursor, and then utilizes surface tension to spheroidize the product. The spray method is divided into spray pyrolysis method, spray drying method and spray melting method. The jet melting method uses radio frequency induced plasma to treat solid alumina into a molten state, and then uses jet high-speed cooling to obtain spherical alumina. This method mainly performs spheroidization treatment on irregularly shaped alumina particles. After treatment, the alumina has high sphericity, but it is difficult to control the particle size scale, which ranges from nanometer to micrometer.

(2) Flame melting method

Currently, flame melting method is commonly used in the market to prepare spherical alumina. Compared with the "jet melting method" with a similar name, the flame melting method directly sprays irregularly shaped alumina powder into the flame, causing the alumina powder to melt into balls in the flame. The process is simple and has more advantages in cost control than the plasma flame spraying method. The products produced by balling have high thermal conductivity, good sphericity, and controllable particle size

(3) Template method

The preparation of spherical alumina by template method first requires a core template, which is wrapped with a layer of shell structured microspheres outside the core template. Then, the core template is removed by physical and chemical methods, and finally hollow microspheres are obtained. According to the characteristics and limitations of the template itself, it is generally divided into hard template method and soft template method

(4) Aerosol decomposition method

The preparation of alumina spheres by aerosol decomposition method mainly uses liquid aluminum alkoxide as raw material. The aluminum alkoxide is first gasified by high-temperature hydrolysis, and then dried or treated at high temperature to form spherical alumina powder. The particle size prepared by this method is in the nanometer range and has not yet been industrialized.

(5) Sol gel method

The sol gel method is to obtain aluminum oxide powder through alcohol washing, aging and heat treatment from the precursor formed by inorganic salt water hydrolysis or polymerization. Due to the use of organic solvents and surfactants in this method, the sphericity of the obtained alumina powder is close to 100%, and the particle size is in the micrometer or millimeter range. The disadvantage of this method is that it is not conducive to the separation and drying of alumina powder.

(6) Hydrothermal method

The hydrothermal method for preparing spherical alumina is to use aluminum salts as raw materials, dissolve and recrystallize the substances in a high-temperature and high-pressure reaction environment, and grow them into spherical alumina particles. The alumina powder produced by hydrothermal method has high purity, controllable shape, and no agglomeration, but requires high temperature and high pressure environment, which is highly dependent on equipment.

(7) Drip ball method

The first step in preparing spherical alumina by droplet method is to prepare pure alumina sol. Starting from acidic alumina sol, the alumina sol is dropped into the oil layer, and the gelling agent is HMTA (hexamethylenetetramine) or a mixture of urea and HMTA. After aging, drying, and calcination, spherical alumina is formed. The droplet method is mainly used to prepare spherical alumina with a particle size of millimeter or larger. During the operation, hot oil is required and the sol must be kept dripping for a long time.

(8) Ball milling method

The ball milling method is to put the raw materials into a ball mill, grind and stir them with a grinding agent, and extract large particles into ultrafine powder. Mechanical ball milling can be used to prepare spherical alumina products with different particle sizes. This method has simple and reliable equipment, is easy to mass produce, and has great development prospects in the future market.

As a core material in the field of thermal conductive fillers, spherical alumina plays an irreplaceable role in the development of high-end industries due to its unique structural advantages, excellent performance, and wide application scenarios.

SAT NANO is a best supplier of spherical alumina powder in China, we can offer nano particle and micro particle, if you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449