In today's paint and plastic industry, which pursues high performance, lightweight, and environmental protection, traditional fillers and reinforcing agents have long been unable to meet the demands of the high-end market. The emergence of nano high-purity magnesium oxide, with its triple advantages of "filling+reinforcement+functionalization", brings performance leaps to coating and plastic products, becoming a key material to solve the contradiction between material strength, weather resistance, and processability.

Why choose nano high-purity magnesium oxide? Traditional fillers such as calcium carbonate and talcum powder often only have an incremental effect and can even lead to a decrease in material performance, known as the "performance upgrade password" for filling and reinforcement. Nano high-purity magnesium oxide, with a purity of over 99.9% and nanoscale characteristics, has achieved a breakthrough of "filling without degradation, reinforcement more efficiently".

Comprehensive improvement in mechanical performance

Nanoparticles can be uniformly dispersed in the matrix, significantly improving the mechanical properties of materials through interface strengthening effects. Adding 5% -8% nano high-purity magnesium oxide to plastic products can increase tensile strength by 25% -40% and impact toughness by more than 30%, solving the problem of material brittleness caused by traditional fillers. In the coating system, it can form a three-dimensional network structure, improving the adhesion of the coating to level 0 and increasing wear resistance by 50%, making it easy to cope with high-frequency friction scenarios.

Double the ability to withstand weather and corrosion

Its excellent chemical stability endows the material with super strong weather resistance. After adding nano high-purity magnesium oxide to outdoor coatings, the UV aging resistance time is extended to over 3000 hours, and the color difference change Δ E is less than 1.5; In plastic products, the temperature resistance range can be expanded to -60 ℃ -180 ℃, and the service life in humid and hot environments can be extended by 2-3 times, perfectly adapting to harsh scenarios such as automotive exterior and outdoor building materials.

Optimization and upgrade of processing performance

Compared with traditional fillers, nano high-purity magnesium oxide has an extremely low oil absorption value (<20g/100g), which can reduce the amount of additives used in coatings and plastic processing, and lower the viscosity of the system. In plastic extrusion molding, the melt flowability is improved by 15% -20%, and the production efficiency is increased by 20%; In coating preparation, the grinding time can be reduced by 30%, and the storage stability is significantly enhanced, with a settling rate of less than 1% per month.

From laboratory to production line: the 'performance revolution' of multi scenario applications

Nano high-purity magnesium oxide, with its multifunctional properties, has been widely applied in various sub fields of coatings and plastics, becoming a "performance standard" for high-end products

Coatings field: Creating high-performance protective coatings

In industrial anti-corrosion coatings, nano high-purity magnesium oxide works synergistically with anti-corrosion pigments to form a dense passivation film, increasing the salt spray testing time from 500 hours to over 1500 hours. It can be used in heavy-duty anti-corrosion scenarios such as marine engineering and chemical equipment. In building exterior wall coatings, it can endow the coating with self-cleaning function, with a residual stain rate of less than 5% after rainwater erosion, and a 40% increase in stain resistance, keeping the exterior wall clean and beautiful for a long time. In automotive coatings, the addition of nano high-purity magnesium oxide to the topcoat can achieve a glossiness of over 95%, improve clarity by 20%, and significantly enhance stone impact resistance, reducing paint damage.

Plastic field: Empowering high-end product upgrades

In engineering plastics, nano high-purity magnesium oxide can replace some glass fibers for the preparation of automotive engine peripheral components, achieving a weight reduction of 10% -15% while ensuring strength, and raising the heat-resistant deformation temperature to above 180 ℃. In the plastic of wires and cables, the volume resistivity increases by 1-2 orders of magnitude after addition, the flame retardant level reaches UL94 V-0 level, and the weather resistance is improved, which can meet the long-term use needs of outdoor cables.

Originating from three core technological breakthroughs: precise control of surface modification

By surface modification with coupling agents such as silane and titanate, the compatibility between nanoparticles and organic matrix is improved by more than 60%, solving the industry problem of easy aggregation of nanomaterials and ensuring uniform and stable performance.

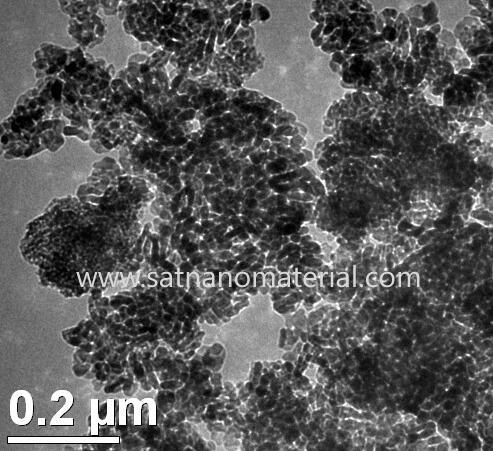

Accurate control of particle size distribution

By adopting advanced hydrothermal synthesis technology, the particle size can be precisely controlled within the range of 10-50nm. The particle size distribution can be customized according to the needs of different coating and plastic systems, maximizing the nano effect.

In the increasingly competitive paint and plastic industry, material performance has become the core competitiveness of product differentiation. Nano high-purity magnesium oxide not only reduces raw material costs (replacing some expensive resins or functional additives), but also endows products with high added value, helping enterprises seize market share in the high-end market.

From industrial anti-corrosion to automobile manufacturing, from building decoration to medical devices, nano high-purity magnesium oxide is reshaping the performance boundaries of coating and plastic materials with the advantage of "small addition, big change". Now, join this material upgrade revolution and make your products comprehensively leading in performance, environmental protection, and cost!

SAT NANO is a best supply of MgO nanopowder in China, we can offer 50nm, 100nm and 1-3um, if you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449