The

aluminum nitride nanopowder has the characteristics of high specific surface area, high hardness, high thermal conductivity and high insulation. It is a diamond-like nitride, stable to 2200 ° C, high room temperature strength, good compatibility with the substrate interface, and can improve compounding. Thermal and dielectric properties, mechanical properties and wear resistance of the material.

Polytetrafluoroethylene PTFE, commonly known as "Plastic King", has a molecular chain of linear structure and is a non-polar polymer. It has good chemical resistance and high and low temperature resistance, and has a small friction factor and excellent dielectric properties. However, its shortcomings such as poor wear resistance, poor creep resistance, and large load-bearing shape limit its application range. In order to improve the comprehensive performance of PTFE, researchers have been working on the modification of it to expand its application in various fields. The filling of inorganic powder modification is a simple and effective method for improving the performance of PTFE. Modified filler of PTFE In addition to common graphite, glass fiber, carbon fiber, molybdenum disulfide, etc., the use of nano-aluminum nitride powder to fill PTFE can also obtain good results.

There are reports:

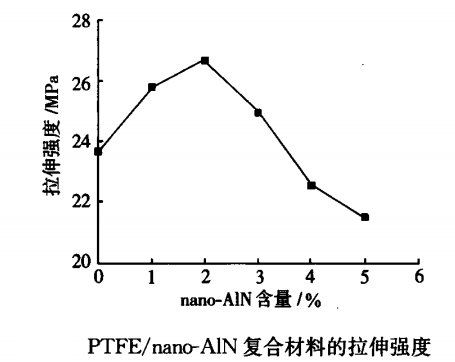

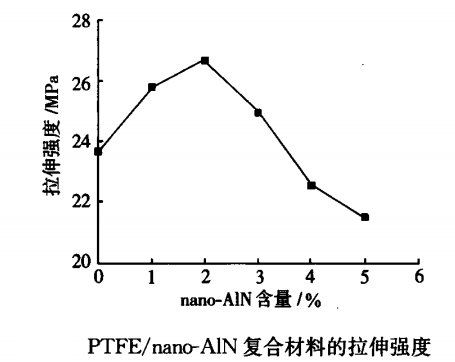

1. The nano aluminum nitride powder added in the PTFE matrix acts as a nucleating agent. The crystallinity of the PTFE/nano-AlN composite material increases first and then decreases with the increase of the content of nano-aluminum nitride. When the content is about 2%, the crystallinity shows a large value, and the crystallinity of the composite material is greater than that of pure PTFE;

2. The addition of aluminum nitride powder improves the comprehensive mechanical properties of the material, and when the content of aluminum nitride fine powder is 2%, a large value occurs, and the Shore hardness (D) and stretching of the PTFE/nano-AlN composite material are exhibited. The strength and impact strength increased by 17.77%, 12.86% and 5.30%, respectively, compared with pure PTFE;

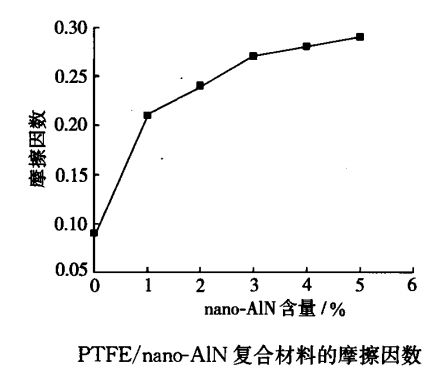

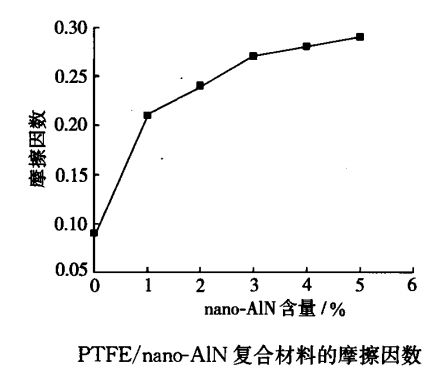

3. After adding nano-aluminum nitride micropowder, the friction factor of PTFE/nano-AlN composites increases, and the wear volume decreases. When the content of nano-aluminum nitride powder is 4%, the wear volume is only 1.4% of pure PTFE. The addition of nano-aluminum nitride powder increases the wear resistance of PTFE by two orders of magnitude;

3. After adding nano-aluminum nitride micropowder, the friction factor of PTFE/nano-AlN composites increases, and the wear volume decreases. When the content of nano-aluminum nitride powder is 4%, the wear volume is only 1.4% of pure PTFE. The addition of nano-aluminum nitride powder increases the wear resistance of PTFE by two orders of magnitude;

Our company can supply aluminum nitride nanopowder 50nm, 200nm, 1-3um, 5um, 10um particle, please feel free to ask us a price.

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449