Tungsten is a compact and strong metal. Because of its excellent corrosion resistance, it has been widely used in many fields such as chemical industry. However, its high hardness and high melting point have hindered its development in the field of 3D printing. But now a research team has challenged this problem and published a paper titled "The Influence of Processing Parameters in Laser Powder Bed Fusion Process on the Densification, Microstructure and Crystal Structure of Pure Tungsten".

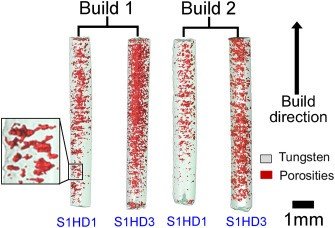

The researchers explained: "We applied the laser powder bed manufacturing process to refractory metals, such as pure tungsten powder in the paper. A process plan for manufacturing high-density parts was proposed and the effect of laser energy density was studied. Researchers have used optical microscope, XCT, SEM and EBSD to evaluate the quality of the process. The results show that the laser energy density can process tungsten materials into good functional parts."

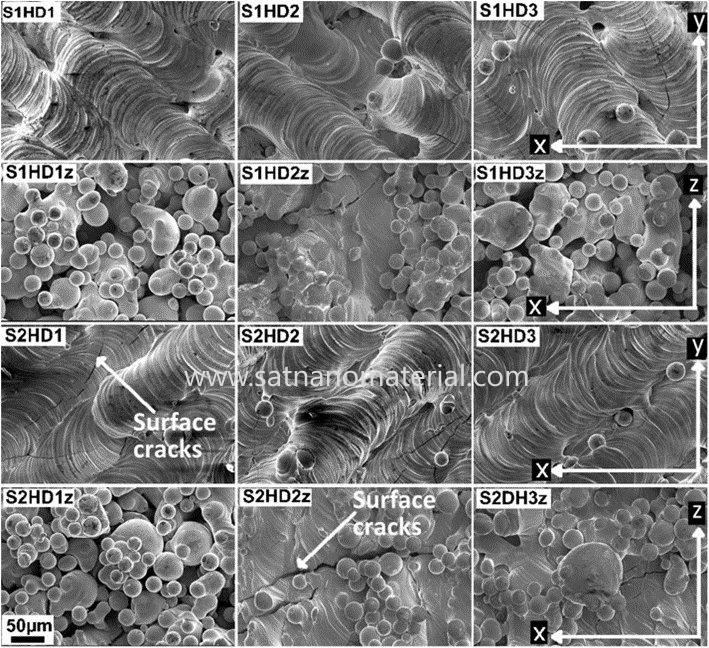

Depending on the process conditions, the volume density and optical density of tungsten vary from 94% to 98%, but due to the existence of microscopic and macroscopic residual stresses, the parts still show defects such as microcracks.

The researchers went on to introduce: "The analysis results of the microstructure and crystal structure show that the melting groove formed under the laser beam is solidified in the ideal orientation through the epitaxial growth mechanism. The EBSD texture analysis results show that tungsten has //Z The orientation is parallel to the construction direction."

Both types of tungsten samples were produced by 3D printing and analyzed using scanning electron microscopes. Although these parts still have the problem of being prone to cracking, the researchers determined that as long as the density and quality of 3D printed samples are improved, they will certainly be useful in the fields of medical radiation protection and nuclear imaging and other plasma environments in the future. They also concluded that laser powder bed fusion technology can be used to manufacture relatively dense tungsten parts.

The researchers also added: "The analysis results of the micro, macro and local textures show the columnar grain structure produced by the epitaxial growth mechanism, which is consistent with the performance of other pure metals. The laser energy with a density of up to 348 J/mm3 can The sample shows a strong //Z fiber structure. It is speculated that this may be related to the shape of the melting tank, the high thermal conductivity of tungsten, low surface tension, and the 67° grating direction rotation of the deposited layer in Renishaw AM. Caused this phenomenon."

3D printing can provide new application opportunities for tungsten materials to produce parts with high precision and complexity. Other researchers have studied the 3D printing process of tungsten materials, some of which have even been commercialized. Despite the challenges, tungsten has proven that it is a valuable 3D printing material, and many experts are interested in its heat resistance.

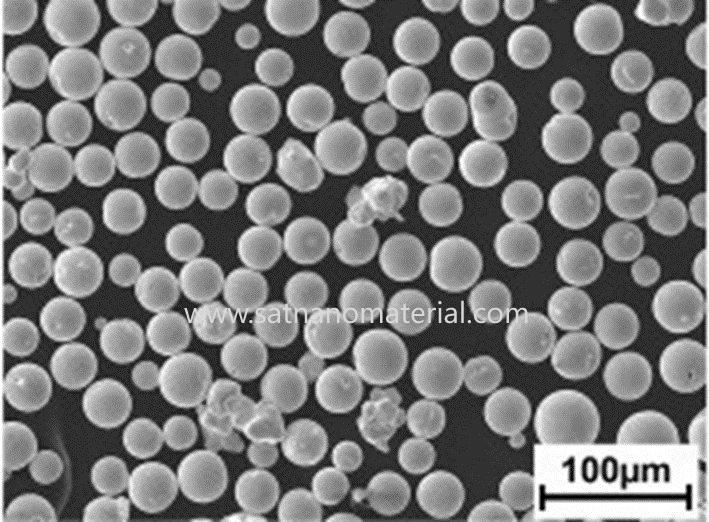

SAT NANO have finished the test on spherical tungsten powder for 3D printer, we offer 5-25um, 15-45um particle, 99.95% purity, if you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449