Aluminum powder is a commonly used filler, widely used in fields such as thermal interface materials and industrial coatings. However, traditional aluminum powder has problems such as high viscosity, poor dispersibility, and poor thermal stability, which limit its effectiveness in some special applications. To address these issues, researchers have carried out many modification methods to improve the performance of aluminum powder.

A relatively effective method for surface modification of aluminum powder is to use silane coupling agents for chemical modification. For example, hexadecyltrimethoxysilane, dodecyltrimethoxysilane, decyltrimethoxysilane, and octyltrimethoxysilane can all be used as modifiers for aluminum powder. These modifiers can enhance the compatibility between aluminum powder and organic matrix, improve its dispersibility and thermal stability, and thus enhance the performance of aluminum powder in composite materials.

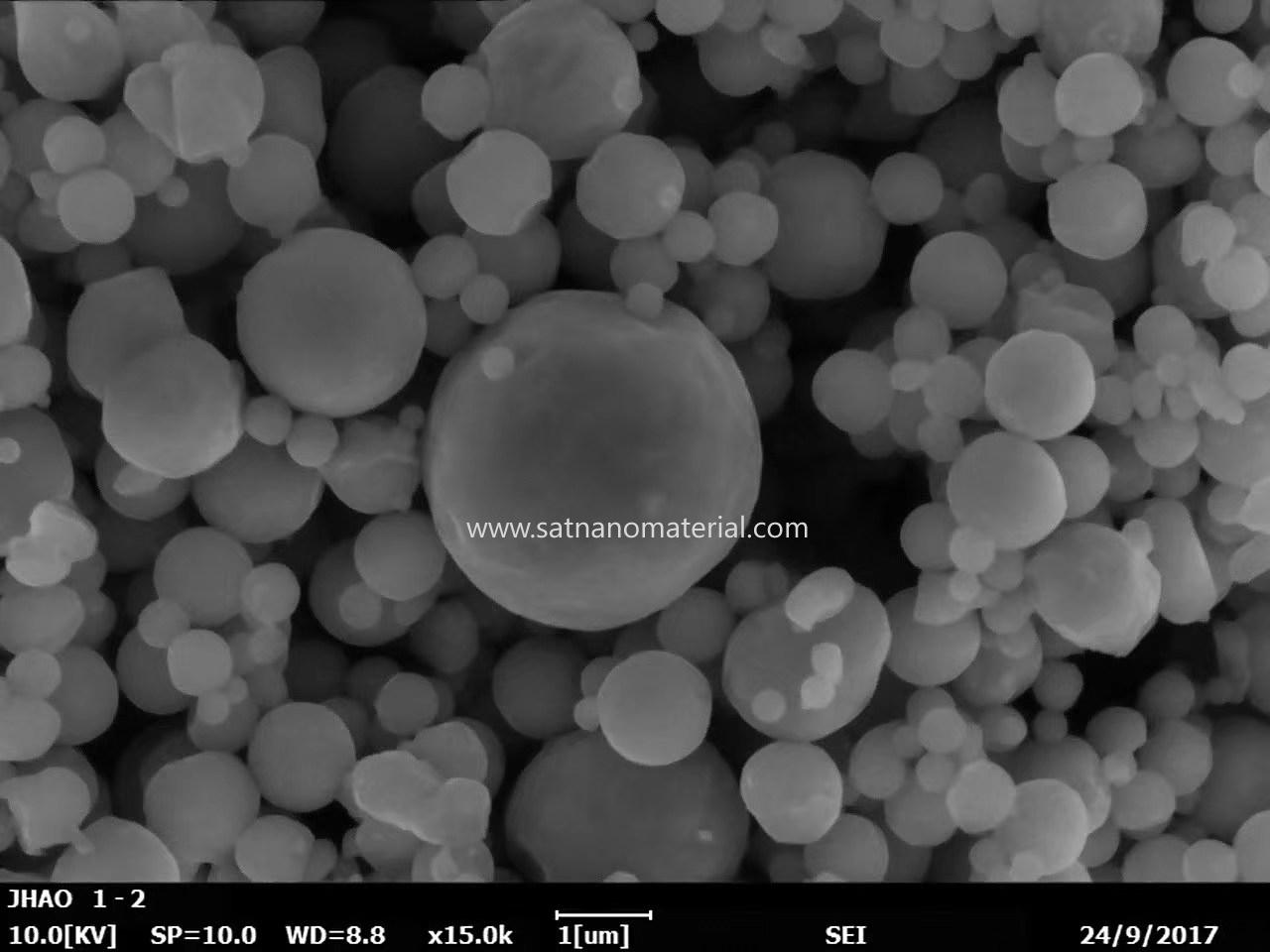

The specific modification method is as follows: first, add aluminum powder with an average particle size of 1-2 μ m to anhydrous ethanol, stir for 2 hours, add silane coupling agent, and stir again for 5 hours. Then, reflux the sample at 75 ℃ and use SEM XRD, FT-IR and other tools were used to test and characterize it. The results showed that aluminum fillers treated with surface chemical properties significantly improved the performance of thermal interface materials, with a viscosity reduction of 77%, a fracture elongation of 154.71%, an increase in thermal conductivity, and an increase of nearly 20% in thermal stability under extreme cold and hot cycling conditions.

In summary, the use of silane coupling agent modification can effectively improve the performance of aluminum powder and enhance its application effect in the field of thermal interface materials. In practical applications, it is necessary to select appropriate silane coupling agents and modification methods based on specific needs, and use SEM XRD, FT-IR, TGA, and contact angle tools were used to test and characterize it to verify its modification effect.

SAT NANO is one of the best supplier of Aluminum powder in China, we can offer 100nm, 1-3um, 10-50um particle and so on, if you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449