Lanthanum belongs to rare earth oxides and is one of the important products of light rare earths. Because of its good physical and chemical properties, it has been widely used in civilian, military and high-tech fields. For example, La2O has been continuously developed in the application of rare glass, ceramics, catalysts, phosphors, lasers, heating elements, cathode materials and electrical contacts. Lanthanum oxide can also reduce exhaust emissions to a certain extent, thereby protecting the environment. However, there are few studies on nano-LaO as a lubricant additive. In this paper, nano-LaO particles are added as an additive to 500SN base oil to study its tribological properties, which will further expand the scope of use of nanoparticles as lubricant additives and further research Its anti-wear and anti-friction mechanism has very important theoretical and practical significance.

1. The choice of nanoparticles

The nano lanthanum oxide particles used in this experiment, the diameter of the nano-LaO particles is about 20-30nm, the purity is 99.99%, and it is prepared by the sol-gel method. Sol-gel includes two stages: hydrolysis reaction and polymerization reaction. The basic process is that the easily hydrolyzed rare earth metal compound (inorganic salt or rare earth metal alkoxide) is gradually gelled through hydrolysis and polycondensation, and then dried, sintered and other treatments to obtain the required material. The low temperature chemical means is in a relatively small size range. Internal tailoring and control of the microstructure of the material, so that the uniformity reaches the nanometer level. Compared with other preparation methods, this method can synthesize inorganic materials at low temperature, design and control the uniformity and particle size of the materials at the molecular level, and finally obtain high-purity nanoparticles.

2. The choice of active agent and its dispersion effect

In order to fully dissolve the nanoparticles into the lubricating oil, we adopt a surface modification method. There are many ways to modify the surface of nanoparticles, but the most commonly used and most convenient method is to use surfactants to modify the surface of nanoparticles to reduce the surface energy of the nanoparticles, so that the nanoparticles can be uniformly dispersed in the medium. In this paper, Tween 60, Span 20, Span 80 and polyether are used to mix according to the mass ratio of 2:1:1:3. According to the hydrophilic-lipophilic balance (HLB) theory, if the three active agents The HLB values are HLB1, HLB2 and HLB3 respectively, and the ratio of the mixture is a:b:c, then

The HLB value of the mixed active agent can be calculated by the following formula: HLB=. It is known that the HLB values of Tween 60, Span 20, Span 80 and polyether are respectively: 14.9, 8.6, 4.3 and 9.5, then according to the above formula, we can calculate that, mixing The latter HLB value is: HLB= =10.2. According to the literature, if the HLB value is between 10 and 13, the active agent is a translucent to transparent dispersion in water. The HLB value of mechanical oil is also between 10-13.

3. Tribological properties of lubricants containing nanoparticles

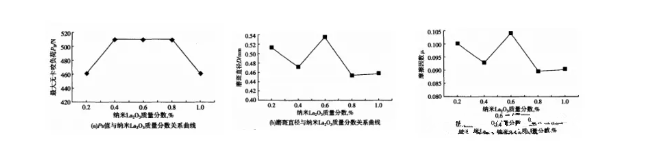

Figure 1 shows the tribological properties of lubricants containing nano La2O3. It can be seen from Figure 1 that when 500SN base oil (P value is 362N, wear scar diameter D is 0.720 mm, friction factor μ is 0.1240) is added with nano-La2O3 particles, as the mass fraction of nanoparticles increases, the Pb value increases . When the mass fraction is 0.4% to 0.8%, the maximum value of 510N is reached. When the content is greater than 0.8%, the Pb value decreases. The wear scar diameter D and friction factor μ both reach the minimum value of 0.454mm and 0.0881 when the mass fraction is 0.8%. It shows that adding nano-La2O3 particles into 500SN base oil can improve the anti-wear and anti-friction performance of lubricating oil, and the best addition amount is 0.8%. Compared with 500SN base oil, its P value is increased by 40.8%, the wear scar diameter is reduced by 36.9%, and the friction factor is reduced by 29%.

4. Mechanism analysis of nano lanthanum oxide particles as lubricant additives

(1) Polishing mechanism. Nano La2O3 particles can play a "micro-polishing" effect on the surface of the friction pair, making the friction surface smoother and reducing friction.

(2) Rolling mechanism. On the surface of the friction pair, nano-La2O3 particles act as a "microbearing" to reduce friction and improve load-carrying capacity.

(3) Repair mechanism. Nano La2O3 particles can fill the pits and play a role in filling and repairing.

(4) Film formation mechanism. Under the action of frictional compressive stress, the highly active nano-La2O3 particles have strong particle adsorption to form a protective film, which can protect the friction surface.

SAT NANO is one of the best supplier of lanthanum oxide nanpowder La2O3 powder in China, we can supply 50nm, 100nm, if you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449