Ultra fine silicon carbide powder is an excellent inorganic material with excellent characteristics such as high chemical inertness, high hardness, and high melting point, making it widely used in the manufacturing industry. However, due to its low surface activity, it is difficult to achieve its excellent performance in certain industrial application scenarios. Therefore, the study of surface modification methods for ultrafine silicon carbide powder is of great significance.

This article will introduce two surface modification methods for ultrafine silicon carbide powder, and test and characterize the modified powder.

Firstly, the method of modification through polyelectrolyte is introduced. This method uses cationic polyelectrolyte polydimethylammonium chloride (PDADMAC) or anionic polyelectrolyte sodium polystyrene sulfonate (PSS) to modify ultrafine silicon carbide powder. The specific process involves stirring PDADMAC or PSS with SiC powder in deionized water for 6 hours, then centrifuging at 3500rpm for 10 minutes, and drying the centrifuged powder at 90 ℃ for 12 hours to obtain polyelectrolyte modified SiC powder. This method can form a polyelectrolyte layer on the surface of ultrafine silicon carbide powder, increase surface activity, and improve its stability and dispersibility.

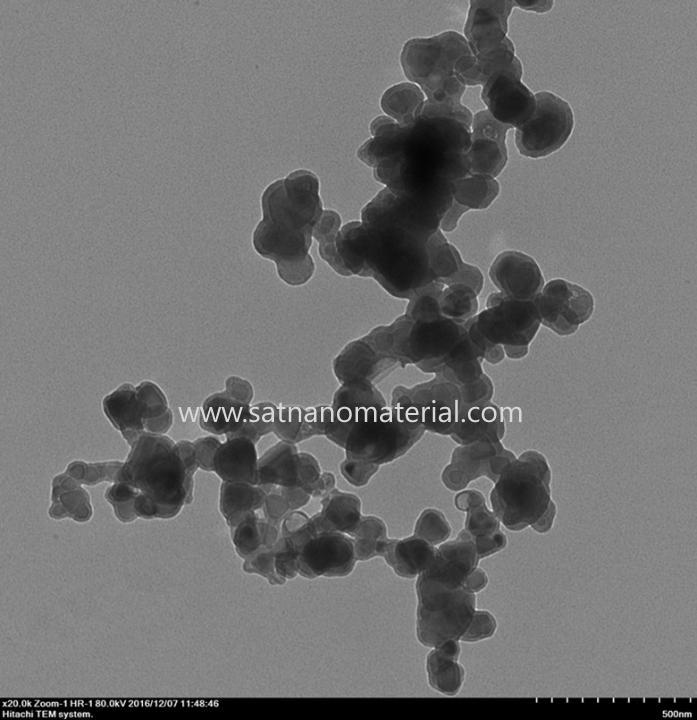

When testing and characterizing the modified ultrafine silicon carbide powder, SEM, XRD, particle size distribution, slurry viscosity, solid content, Zeta potential and other methods were mainly used. Among them, SEM observation results show that the surface of the modified silicon carbide powder is smoother and the particles are more uniform. The XRD test results showed that the crystallization performance of the modified silicon carbide powder did not change. The particle size distribution results show that the modified silicon carbide powder has a more uniform particle distribution and a more stable particle size. The test results of slurry viscosity, solid content, Zeta potential and other indicators also show that the modified silicon carbide powder has better dispersibility and stability.

Modification effect: (1) PDADMAC is adsorbed onto the surface of SiC particles through electrostatic attraction interaction. Due to the high affinity adsorption between the two, the adsorption configuration of PDADMAC on SiC surface is flat, and the adsorption amount, adsorption configuration, and modification effect do not change with the change of molecular weight. The modified pH value is 11, the addition amount is 0.24wt%, the temperature is 90 ℃, and the modification time is 6 hours. Because the adsorption of PDADMAC makes the charge on the surface of SiC reverse, the modified SiC powder is dissolved in water medium to adjust the pH value to 3, and the modified SiC powder is uniformly dispersed in water medium through the electrostatic steric stabilization mechanism, and 50 vol.% is prepared SiC slurry with a viscosity of 0.138Pa. s under solid phase content. (2) Sodium polystyrene sulfonate (PSS) is adsorbed onto the surface of SiC particles through hydrogen bonding and van der Waals forces. Due to the electrostatic repulsive interaction between the two, the adsorption configuration of PSS on the surface of SiC is circular and tail shaped, and as the molecular weight of PSS increases, its circular configuration on the surface of SiC particles expands, the adsorption capacity increases, and the modification effect improves. Using PSS with a molecular weight of Mw=1000000, the pH value is not adjusted during the modification process. The addition amount is 0.3wt%, the temperature is 90 ℃, and the modification time is 6 hours. The modified SiC powder was dissolved in the water medium, and the pH value was adjusted to 11. The modified SiC powder was uniformly dispersed in the water medium through the electrostatic steric stabilization mechanism. A SiC slurry with a high solid content (45vol.%) was obtained, corresponding to a slurry viscosity of 0.098Pa. s. (3) Non ionic surfactant octadecylamine polyoxyethylene ether (AC1830) and anionic polyelectrolyte sodium polystyrene sulfonate (PSS) were used as modifiers to modify silicon carbide powder. The adsorption of AC1830 is not affected by surface charges, can shield some charges, and can serve as an adsorption site for PSS, promoting the adsorption of PSS on SiC surface. Prepared a viscosity of 0.039Pa. s and a solid content of 50vol.% SiC slurry suitable for injection molding. The Zeta potential method indicates that the isoelectric point (IEP) of SiC powder modified by this method is significantly shifted to the left. The settlement experiment shows that the dispersion stability is significantly improved. The contact angle measurement shows that the modifier successfully adsorbs on the surface of the powder and provides hydrophilic groups, thereby improving the wettability of the powder. The adsorption test results indicate that the isothermal and kinetic adsorption models of PSS on SiC powder and AC1830 modified SiC powder conform to the Langmuir model and pseudo second order (PSO) model. The adsorption of AC1830 on SiC surface improved the adsorption capacity of PSS.

SAT NANO can supply high quality Ultra fine silicon carbide powder 50nm, 100nm, 1-3um particle size, if you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449