With the rapid development of modern industry and technology, different industries have increasingly high performance requirements for powder materials. In addition to having extremely low impurity content, fine particle size, and narrow particle size distribution, powder materials also need to have a certain particle morphology. Spherical powders have been widely used in high-end industries such as electronic components, aerospace, and 3D printing due to their excellent performance in surface morphology, particle size distribution, and flowability. In the industrial field, atomization method is a widely used and process stable method for producing large spherical powders. However, for high melting point ceramic materials or refractory metals such as molybdenum and tungsten, the atomization method is difficult to handle due to limitations in process technology, tooling equipment, and other factors. Plasma spheroidization technology, with its core advantages of ultra-high temperature and high energy density, can achieve spheroidization and densification of refractory material powders. It is one of the effective ways to prepare spherical powders with uniform composition, high sphericity, and few defects, and has attracted much attention in high-end manufacturing and advanced materials fields.

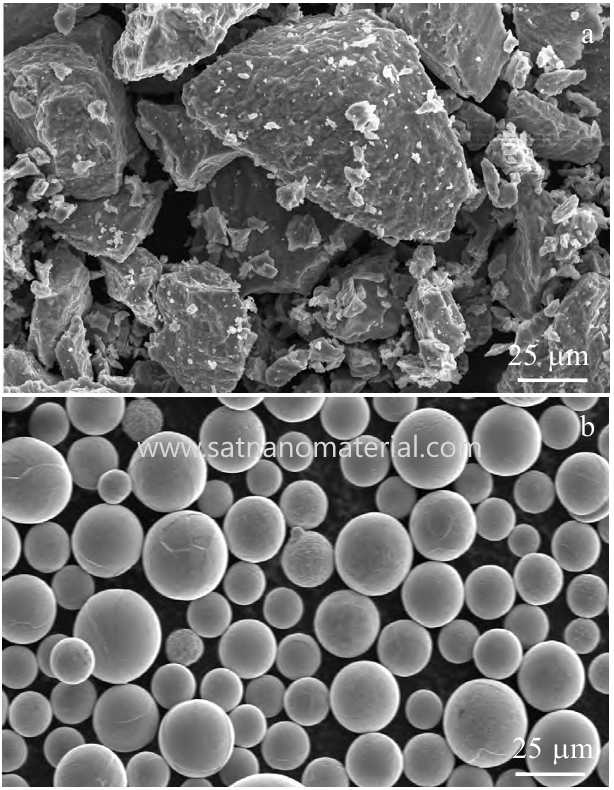

Plasma, also known as plasma, is the fourth largest state of matter outside of solid, liquid, and gas states. It is a highly ionized gas composed of charged particles (mainly positive ions and free electrons). It has the characteristics of high temperature, large volume of plasma torch, high energy density, fast heat transfer and cooling speed. It can be used as a high-temperature heat source to melt and spheroidize raw materials, and can also participate in chemical reactions under specific atmospheres to synthesize various ultrafine compound powders. The core process of this technology is to use the ultra-high temperature of plasma to instantly melt or even vaporize irregularly shaped raw material powders. The molten droplets spontaneously contract into spherical shapes under the action of surface tension, and then solidify in rapid cooling, ultimately obtaining high-quality powders with high sphericity and few defects.

This technology has many advantages: 1) Improving fluidity: it effectively reduces the segregation and agglomeration of powders, especially fine powders, and effectively controls the process quality during powder metallurgy processes such as powder mixing, loading, and compaction; 2) Improve the compaction density; 3) Reduce internal defects; 4) Effective improvement of morphology: making the microstructure of the material into a standard spherical shape; 5) Reduce oxygen content: The introduction of a reducing atmosphere during the preparation process can greatly reduce the content of oxygen elements.

According to the generation method of plasma, it can be divided into direct current arc thermal plasma spheroidization method and radio frequency induction plasma spheroidization method.

DC arc thermal plasma spheroidization method

The main principle is to generate high temperature through arc discharge located between the cathode tip and the anode, causing the gas in the reaction chamber to transform into a plasma state, and forming a jet at the nozzle under the blowing of the gas flow. And the raw materials evaporate and decompose into gaseous atoms, and the supersaturated vapor flows to the lower temperature parts of the reaction chamber, where it nucleates and grows into the desired spherical particles again.

Radio frequency induced plasma spheroidization method

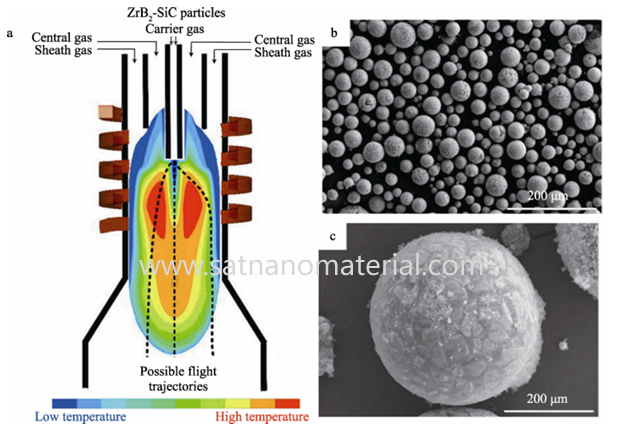

This method utilizes radio frequency (1-500 MHz) magnetic field excitation to generate inductively coupled plasma. The main principle is that the powder raw material undergoes instantaneous melting and shrinkage processes under the action of radio frequency electric field, forming a spherical structure, which is then cooled and solidified to obtain spherical powder, and finally falls into the collection device.

Characteristics: Radio frequency plasma has many advantages such as stable heat source, high energy density, high heating temperature, fast cooling speed, and no electrode pollution. It can also achieve good spheroidization effect on refractory metals, which can change the morphology of irregular powder materials, increase the sphericity of powder particles, and reduce defective powders. This technology has been widely applied in the preparation of spherical powders of refractory metals and ceramic materials, such as tungsten powder, chromium powder, titanium powder and its alloys, high-purity quartz, and alumina.

Although plasma technology still faces challenges such as complex equipment, high investment costs, and the need to improve productivity, its unique advantages in preparing high spheroidization rate and high-density powders have attracted much attention.

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449