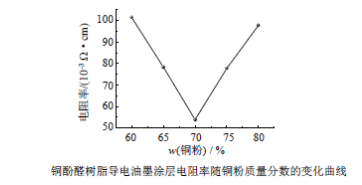

The appropriate amount of copper powder added is between 60% and 80%. When it is less than 60%, the copper powder is insufficient, the conductive ink is too thin, the copper powder in the formed conductive coating cannot be fully contacted, and the resistivity of the conductive coating is too large. When the copper powder is added in an amount greater than 80%, the conductive ink becomes viscous and the painting performance is not good. It is difficult to form a conductive coating through screen printing, and the conductive coating has a large resistivity or even non-conductive. It can be seen from the figure that with the increase in the amount of copper powder added, the resistivity of the conductive coating first drops and then rises. When the amount of copper powder added is 70%, the resistivity of the copper powder conductive ink coating reaches 53.865×10–3Ω·cm at the lowest.

In the specific application, the appropriate amount of copper powder should be selected, too little or too much is not conducive to the resistivity of the conductive coating. If you have any enquiry of copper powder, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449