CAS 7440-05-3 Pd nanopowder Ultrafine Palladium as catalyst

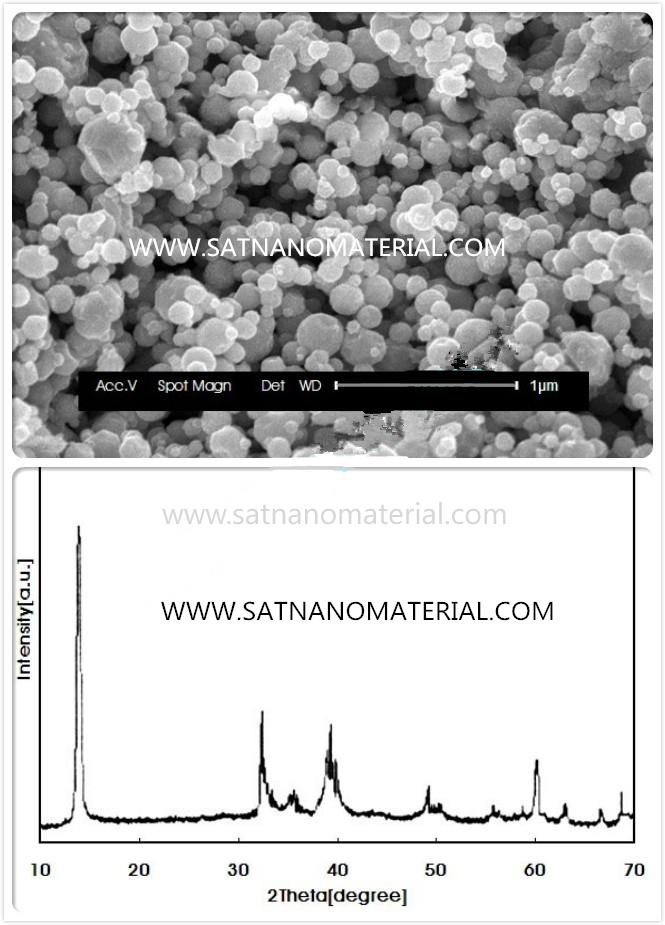

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

We can supply different size products of niobium silicide powder according to client's requirements. Size:1-3um; Purity:99.5%;Shape:granular CAS No:12034-80-9;ENINEC No.:234-812-3

Ni2Si particle,99.5% purity,granular shape,is used for Microelectronic integrated circuit, nickel silicide film,etc. Size:1-10um; CAS No:12059-14-2;ENINEC No.:235-033-1

Size:200nm, 1-3um

Purity:99.9%

CAS No:12138-09-9

ENINEC No.:235-243-3

Appearance:black Powder

Shape:Spherical

Brand:

SAT NANOItem NO.:

SP4216B-200NPayment:

TT, Paypal, WUProduct Origin:

ChinaColor:

Black PowderShipping Port:

Shenzhen, ShanghaiLead Time:

1-5daysMin Order:

1kgSpecification of MoS2 powder:

| Part No. | Particle |

Purity (%) |

SSA (m2/g) |

Bulk density (g/cm3) |

Density (g/cm3) |

Crystal | Color |

| SP4216B-200N | 200nm | 99.9 | 13 | 1.2 | 5 | Spherical | black |

|

SP4216B-1U |

1-3um | 99.5 | 6 | 1.4 | 5 | Spherical | black |

Molybdenum disulfide powder is the dark gray shiny powder, density 4.8, melting point 1185 ℃, 450 ℃ sublimation, Mohs hardness of 1 to 1.5. Under normal circumstances, the friction coefficient of 0.03 to 0.05. Chemical stability and good thermal stability.

Application of MoS2 powder:

1. Application in lubricants: not only can improve the maximum bite load of lubricating oil, but also can reduce the wear and improve the friction properties of the material.

2. Nano-molybdenum disulfide can be used as heavy oil conversion, fuel refining of highly active hydrogenation catalyst, nano-MoS2 in the process of carbon monoxide methanation as a catalyst, with high selectivity and reactivity.

3. Nano-molybdenum disulfide is a catalyst for coal liquefaction.

Storage conditions:

MoS2 powder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449