CAS 7440-05-3 Pd nanopowder Ultrafine Palladium as catalyst

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

We can supply different size products of niobium silicide powder according to client's requirements. Size:1-3um; Purity:99.5%;Shape:granular CAS No:12034-80-9;ENINEC No.:234-812-3

Ni2Si particle,99.5% purity,granular shape,is used for Microelectronic integrated circuit, nickel silicide film,etc. Size:1-10um; CAS No:12059-14-2;ENINEC No.:235-033-1

Buy superfine spherical aluminum nanoparticle used for rocket propellant, size:50nm, 80nm, 100nm, 200nm, Purity:99.9%, fast delivery, good quality, low price. Please click it to check the specification.

Brand:

SAT NANOItem NO.:

MP13-100NPayment:

TT, Paypal, WUProduct Origin:

ChinaColor:

blackShipping Port:

Shenzhen, ShanghaiLead Time:

1-5daysMin Order:

100gSpecification of superfine aluminum powder:

CAS No:7429-90-5

ENINEC No.:231-072-3

Appearance: grey black powder

Shape:Spherical

| Part No. | Particle |

Purity (%) |

SSA (m2/g) |

Bulk density (g/cm3) |

Density (g/cm3) |

Crystal | Color |

| MP13-50N | 50nm |

99.9 |

20 | 0.1 | 2.7 | Spherical | black |

|

MP13-100N |

100nm | 99.9 | 15 | 2 | 2.7 | Spherical | black |

|

MP13-1U |

1-3um | 99.9 | 9 | 4.2 | 2.7 | Spherical |

grey black |

The nano aluminum powder has high purity, uniform particle size distribution and easy to disperse.

Application of superfine aluminum powder:

1. Nano aluminum powder and metal oxide have successful high explosiveness because its surface area is much larger than traditional thermite powder, so it can provide ten times the burning rate of the existing gunpowder propellant. This is the so-called "nano high explosive".

2. Widely used in high-grade metal coatings, composite materials (thermally sprayed composite metal powder, ceramic composite tubes), military industry (fillers), chemicals (various chemical catalysts, pesticides), metallurgy (aluminum thermal metallurgy, steel deoxidizer), Shipbuilding (conductive) coatings), refractory materials (steel furnace carbon bricks), new building materials (aerated concrete gas agent), anti-corrosion materials, etc.

3. Compatibility of other ingredients with nano aluminum powder and propellant 3 Carefully prepared dense non-porous propellant. Adding high-activity nano aluminum content can increase the energy of propellant. The higher the content, the higher the energy, the higher the propellant burning rate. The higher the content, the higher the burning rate. The smaller the burning rate pressure index. The smaller the tablet diameter. The ratio is higher and the mechanical properties of the propellant are improved.

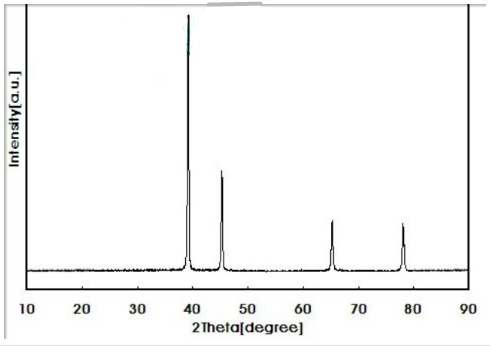

SEM & XRD of superfine aluminum powder:

Storage conditions:

superfine aluminum powder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449