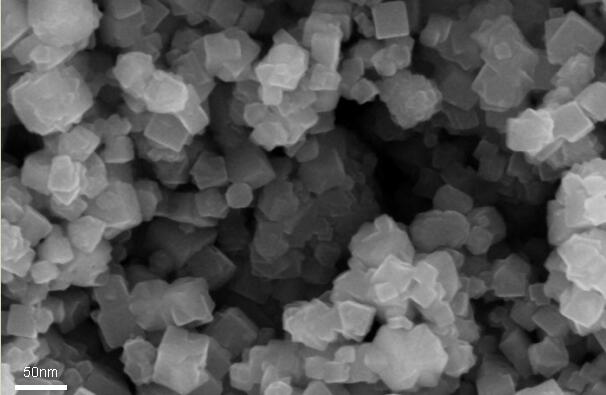

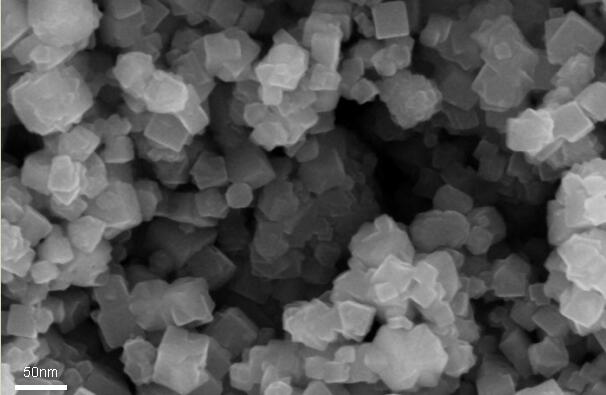

After purchasing our company's nano iron oxide powder, the customer found that the particle size was larger during testing. Why is that? Because the particle size of nano powder is very fine, it is easy to agglomerate, so the large particle size tested is the particle size after agglomeration. So how can we effectively disperse nano iron oxide powder? Next, we will introduce how to use ultrasonic waves to disperse nano iron oxide (Fe3O4) powder,

The steps are as follows:

1. Prepare materials and equipment

-Nano Fe3O4 powder

-Dispersion medium: such as water, ethanol, etc

-Dispersants: such as SDS, CTAB, etc. (optional)

-Ultrasonic cleaning machine or ultrasonic probe

2. Prepare suspension

-Add nano Fe3O4 powder into the dispersion medium, with a concentration typically ranging from 0.1 to 1 wt%.

-If a dispersant is needed, add it in proportion (e.g. 0.1-1 wt%).

3. Preliminary mixing

-Use a magnetic stirrer or manual stirring to preliminarily mix the powder with the medium.

4. Ultrasonic dispersion

Ultrasonic cleaning machine:

1. Place the suspension into the tank of the cleaning machine.

2. Set the ultrasound power and time (usually 100-500 W, 10-30 minutes).

3. Start the device and perform ultrasonic treatment.

Ultrasonic probe:

1. Immerse the probe into the suspension and ensure that the probe is at an appropriate distance from the liquid surface.

2. Set the ultrasound power and time (usually 50-200 W and 5-15 minutes).

3. Start the device and perform ultrasonic treatment.

5. Cooling

-Heat is generated during the ultrasonic treatment process, and intermittent cooling or the use of an ice bath is necessary to prevent overheating.

6. Post processing

-After dispersion, undissolved large particles can be removed by centrifugation or filtration.

Example steps

1. Add 0.1 g of nano Fe3O4 powder to 100 mL of water.

2. Add 0.1 g SDS as a dispersant.

3. Magnetic stirring for 10 minutes, preliminary mixing.

4. Use an ultrasonic cleaning machine, set the power to 300 W, and sonicate for 20 minutes.

5. Pause every 5 minutes to cool the suspension.

6. After dispersion, let it stand and observe whether it is uniform.

matters needing attention

-Ultrasonic power and time * *: Excessive or prolonged use may cause particle breakage or agglomeration.

-Temperature control: Avoid overheating and cool down in a timely manner.

-Safe operation: Avoid using the ultrasound probe without load to prevent damage.

Through these steps, nano iron oxide powder can be effectively dispersed.

SAT NANO is one of the best supplier of iron oxide Fe3O4 nanopowder in China, we can offer 10-20nm, 50nm, 100nm, if you have any enquiry, please feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449