In copper-clad laminates, spherical silicon micro powders with excellent fluidity can achieve high filling in the resin matrix of copper-clad laminates, thereby further reducing production costs, basic thermal expansion coefficients, and dielectric constants. One of the most commonly used systems for high-frequency copper-clad laminates is PTFE resin, which requires a high filling amount of filler. However, as the filling amount increases, the viscosity of the system will sharply increase, and the flowability and permeability of the material will deteriorate. Spherical silicon micro powders are difficult to disperse in the resin and are prone to agglomeration problems. To solve the above problems, surface treatment of spherical silicon micro powder is usually required.

By surface treatment modification, the interaction between spherical silicon micro powders can be reduced, effectively preventing agglomeration, lowering the viscosity of the entire system, improving the flowability of the system, and enhancing the compatibility between spherical silicon micro powders and PTFE resin matrix, so that particles can be uniformly dispersed in the adhesive.

In epoxy sealant, in order to improve the filling rate of spherical silicon micro powder in the epoxy sealant while maintaining good flowability of the sealant, some products will use different particle sizes of spherical silicon micro powder to form a certain gradation relationship to improve the stacking efficiency, thereby increasing the filling amount of spherical silicon micro powder, improving the thermal conductivity of the epoxy sealant, reducing the thermal expansion coefficient, and controlling costs.

Before adding epoxy resin matrix, spherical silicon micro powder generally needs to undergo surface modification to improve its interface bonding with the epoxy resin matrix, in order to obtain better physical and mechanical properties and thermal conductivity.

1.Coupling agent modification

Surface modification of inorganic powders through chemical treatment is an effective method to improve their dispersion stability in the matrix medium. Coupling agent modification, as a typical chemical modification method, has the widest application range and the most complete industrial system. Coupling agents can be divided into silane coupling agents, titanate coupling agents, aluminate coupling agents, etc. according to their molecular chemical structure.

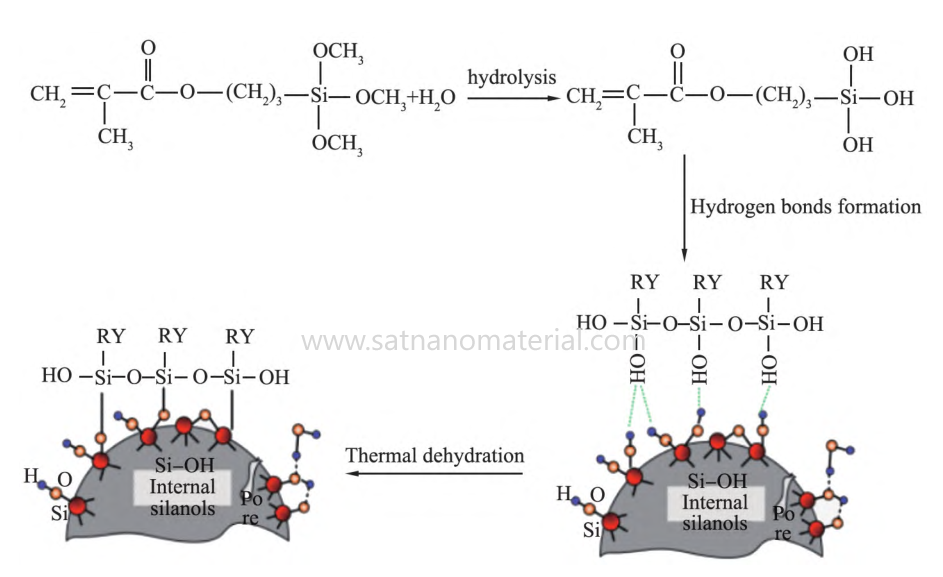

Silane coupling agent modification: There are various types of silane coupling agents, which are flexible in selection and have a wider range of applications. Coupling agents containing corresponding functional groups can be selected as surface modifiers according to different matrix media. The silanization modification of silica is achieved through hydrolysis and condensation reactions of silane coupling agents. In addition, in the presence of water, silane coupling agents undergo hydrolysis reactions to produce silanol, which easily undergoes dehydration condensation reactions with hydroxyl groups on the surface of silica. At the same time, silanol also undergoes dehydration self polymerization.

Modification of Titanate Coupling Agent: The main mechanism of action between titanate coupling agent and silica micro powder is the chemical reaction between the hydrophilic inorganic groups (RO) m in the structure of titanate molecules and the hydroxyl groups on the surface of silica micro powder, forming a monolayer on the surface of silica micro powder and releasing isopropanol.

2.Polymer graft modification

Specific methods can be used to graft synthesized polymers onto the surface of inorganic powders, which enhances the chemical functionality of both inorganic and organic materials and alters their surface topology. This polymer grafted inorganic powder particle is considered an organic-inorganic composite particle.

Wu Wei et al. used graft polymerization modification method to modify the surface of ultrafine silica. The results indicate that this process can achieve surface polymerization and grafting modification of ultrafine silica, and the free radical polymerization reaction between styrene and the double bond of silane coupling agent pre grafted on the surface of ultrafine silica can effectively disperse the aggregates of ultrafine silica.

3.Chemical corrosion modification

The principle of chemical corrosion method is to use highly oxidizing or reactive reagents to oxidize or etch the surface of materials, thereby "exposing" new active groups.

Wang treated SiO2 microspheres with hot NaOH solution. Studied the surface properties of microspheres. The results showed that the surface activity and hydroxylation of SiO2 microspheres were enhanced after surface etching, which increased the anchoring sites and dispersibility of the nanoparticles.

4.surface coating

The principle of surface coating method is to use active substances with viscosity and rich active groups to form a coating layer on the surface of the material. After treatment, the material can continue surface modification based on the active substances.

SAT NANO used dopamine to self polymerize on the surface of nano silica particles to form surface modified nano silica modified particles PD-SiO2, and melt blended the modified particles with polypropylene/ethylene octene copolymer to prepare polypropylene composite materials. The results showed that polydopamine did not damage the structure of nano silica and successfully adhered to the surface; Polydopamine modification improves the hydrophilicity of the composite material, reduces the crystallization temperature, and increases the crystallinity.

SAT NANO is a best supplier of spherical silica powder in China, we can offer 20-30nm, 100nm, 300nm, 500nm, 800nm with 99.9%, if you have any enquiry, pleasel feel free to contact us at admin@satnano.com

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449