CAS 7440-05-3 Pd nanopowder Ultrafine Palladium as catalyst

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

We can supply different size products of niobium silicide powder according to client's requirements. Size:1-3um; Purity:99.5%;Shape:granular CAS No:12034-80-9;ENINEC No.:234-812-3

Ni2Si particle,99.5% purity,granular shape,is used for Microelectronic integrated circuit, nickel silicide film,etc. Size:1-10um; CAS No:12059-14-2;ENINEC No.:235-033-1

Size:50nm, 100nm, 200nm, 1-3um

Purity:99.9% Shape:Hexagonal

CAS No:12070-12-1 ENINEC No.:235-124-6

Appearance:black Powder

Brand:

SAT NANOItem NO.:

CP7406-100NPayment:

TT, Paypal, WUProduct Origin:

ChinaColor:

Black PowderShipping Port:

Shenzhen, ShanghaiLead Time:

1-5daysMin Order:

1kgSpecification of tungsten carbide nanoparticles:

| Part No. | Particle |

Purity (%) |

SSA (m2/g) |

Bulk density (g/cm3) |

Density (g/cm3) |

Crystal | Color |

| CP7406-50N | 50nm | 99.9 | 60 | 1.5 | 13 | Hexagonal | black |

|

CP1406P-100N |

100nm | 99.9 | 40 | 2.0 | 13 | Hexagonal | black |

|

CP7406-200N |

200nm | 99.9 | 24 | 3.2 | 13 | Hexagonal | black |

|

CP1406P-1U |

1-3um | 99.9 | 9 | 4.9 | 13 | Hexagonal | black |

The product has high purity, uniform particle size and good dispersibility. It is an important raw material for the production of cemented carbide. The nano-tungsten carbide powder can make the cemented carbide have many more excellent characteristics, insoluble in cold water, strong acid resistance, high hardness and elastic modulus. Big. In addition to high hardness, tungsten carbide is resistant to abrasion, corrosion, and high temperature.

Application of tungsten carbide nanoparticles:

1 nanometer tungsten carbide is applied to composite materials to improve its performance: nano tungsten carbide-cobalt composite powder is the main raw material for preparing high performance cemented carbide and wear resistant coating. The nano-tungsten carbide-cobalt composite powder has shown good effect as a wear-resistant coating material. The coating prepared by the rapid melting and rapid condensation thermal spraying technology maintains the nanostructure characteristics of the powder, thereby significantly improving the hardness. The performance of the alloy wear resistant coating. Domestically, the production of nano-tungsten carbide-cobalt composite powder products has been used to prepare cemented carbide and wear-resistant coatings. Such as: cutting tools, computers, machinery and other industries;

2 Tungsten carbide is suitable for machining at high temperatures, and can be used to make cutting tools, structural materials for kiln, jet engines, gas turbines, nozzles, and the like.

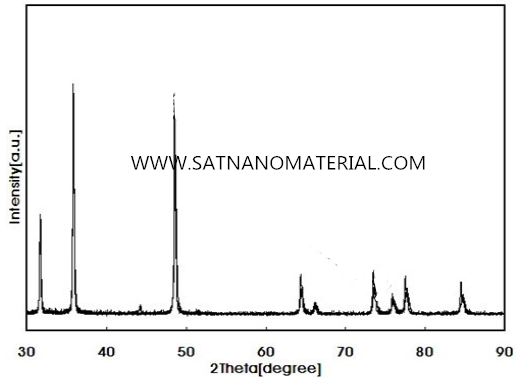

SEM & XRD of tungsten carbide nanoparticles:

Storage conditions:

tungsten carbide nanoparticles should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449