CAS 7440-05-3 Pd nanopowder Ultrafine Palladium as catalyst

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

We can supply different size products of niobium silicide powder according to client's requirements. Size:1-3um; Purity:99.5%;Shape:granular CAS No:12034-80-9;ENINEC No.:234-812-3

Ni2Si particle,99.5% purity,granular shape,is used for Microelectronic integrated circuit, nickel silicide film,etc. Size:1-10um; CAS No:12059-14-2;ENINEC No.:235-033-1

Size:20nm, 80-100nm, 1-2um, 5um, 10um

Purity:99.99%

CAS No:7440-22-4

ENINEC No.:231-131-3

Appearance:Red powder

Shape:Spherical

Brand:

SAT NANOItem NO.:

MP47-20NPayment:

TT, Paypal, WUProduct Origin:

ChinaColor:

greyShipping Port:

Shenzhen, ShanghaiLead Time:

1-5daysMin Order:

100gSpecification of silver nanoparticles:

| Part No. | Particle |

Purity (%) |

SSA (m2/g) |

Bulk density (g/cm3) |

Density (g/cm3) |

Crystal | Color |

| MP47-20N | 20nm | >99.99 | 30 | 0.5 | 10.5 | Spherical | grey |

|

MP47-80N |

80nm |

>99.99 |

20 | 1.2 | 10.5 | Spherical | grey |

|

MP47-1U |

1um | >99.99 | 10 | 2.65 | 10.5 | Spherical | grey |

|

MP47-5U |

5um | >99.99 | 8 | 2.85 | 10.5 | Near Spherical | grey |

1. Silver powder has low pine ratio and good fluidity;

2. The surface of the silver powder conductive layer is flat and the conductivity is good;

3. High-performance conductive filler material with good oxidation resistance. Widely used in electronic paste, electronic products, conductive, electromagnetic shielding, antibacterial anti-virus.

Application of silver nanoparticles:

1. Film, microfiber;

2. ABS, PC, PVC and other plastic substrates;

3. Antibacterial and bacteriostatic agents;

4. Used as high temperature sintered conductive silver paste and low temperature polymer conductive silver paste.

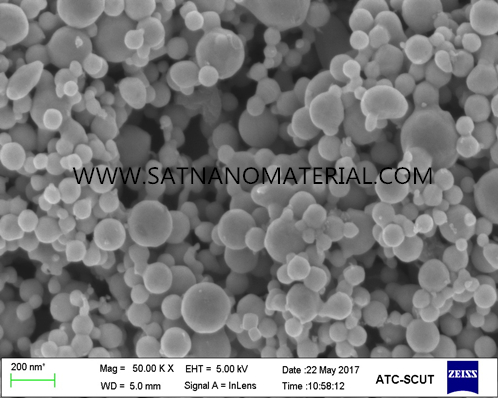

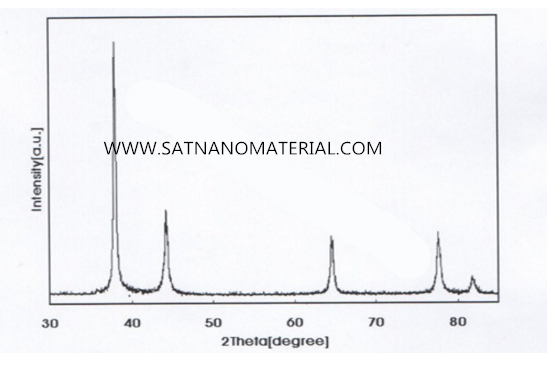

SEM & XRD of silver nanoparticles:

Storage conditions:

silver nanoparticles should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449