CAS 7440-05-3 Pd nanopowder Ultrafine Palladium as catalyst

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

Size:20-30nm Purity:99.95% CAS No:7440-05-3 ENINEC No.:231-115-6 Appearance:black Powder Shape:spherical

We can supply different size products of niobium silicide powder according to client's requirements. Size:1-3um; Purity:99.5%;Shape:granular CAS No:12034-80-9;ENINEC No.:234-812-3

Ni2Si particle,99.5% purity,granular shape,is used for Microelectronic integrated circuit, nickel silicide film,etc. Size:1-10um; CAS No:12059-14-2;ENINEC No.:235-033-1

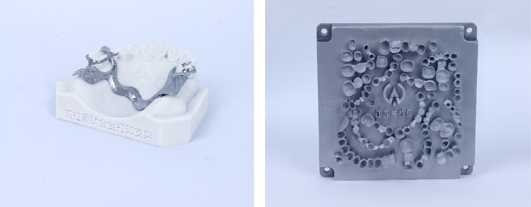

Buy Spherical Cobalt chromium Molybdenum alloy powder for 3D printing 0-25um and 15-53um, 45-105um, 75-150um size, 99.9% purity, high quality and good price and fast delivery time, please check the specification.

Brand:

SAT NANOItem NO.:

CoCrMo-1UPayment:

TT, Paypal, WUProduct Origin:

ChinaColor:

grey PowderShipping Port:

Shenzhen, ShanghaiLead Time:

1-5daysMin Order:

1kgSpecification of Spherical Cobalt chromium Molybdenum alloy powder:

Size:0-25um, 15-53um, 45-105um, 75-150um (various particle sizes can be customized according to customer requirements)

Color:grey, Shape:spherical, flowability:<=35s/50g

| Co | Cr | Mo | W | Si | Fe | C | P | Mn |

| Balance | 26-30% | 4-7% | <0.2% | <1% | >075% | <0.1% | <0.03% | <0.3% |

Application of Spherical Cobalt chromium Molybdenum alloy powder:

1.Manufacturing high-speed cutting tools: Due to the high hardness and wear resistance of cobalt chromium molybdenum alloy powder, it can be used to manufacture high-speed cutting tools, including drill bits, milling cutters, mechanical machining tools, etc.

2.Manufacturing valves and pump housings: Due to the corrosion resistance of cobalt chromium molybdenum alloy powder, it can be used to manufacture mechanical parts with high corrosion resistance requirements such as valves and pump housings.

3.Manufacturing petrochemical equipment: Due to the high temperature strength and corrosion resistance of cobalt chromium molybdenum alloy powder, it can be used to manufacture petrochemical equipment, including catalysts and reactors.

4.Manufacturing aerospace parts: Due to the high temperature resistance of cobalt chromium molybdenum alloy powder, it can be used to manufacture turbine blades, engine parts, and other components in aerospace equipment.

5.Manufacturing medical equipment: Due to the good biocompatibility of cobalt chromium molybdenum alloy powder, it can be used to manufacture medical equipment such as orthopedic implants and dental metal restorations.

Storage conditions:

Spherical Cobalt chromium Molybdenum alloy powder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.

online service

online service 13929258449

13929258449 admin@satnano.com

admin@satnano.com + 8613929258449

+ 8613929258449